Model A & AA

Ford Garage

Three Speed Transmission Case Variations

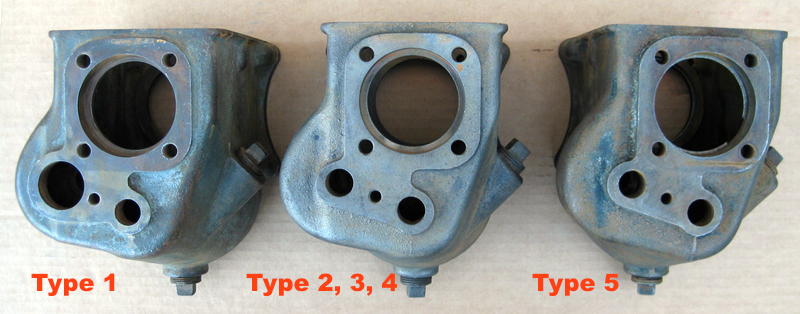

This page details the five major types of the A-7006 three-speed transmission case used during Model A Ford production.

All Model A transmission cases were cast iron. In addition to being used in all Model A cars, the three-speed transmission was used in Model AA trucks until the introduction of the four-speed truck transmission in 1929.

The table below shows the progression of identifying features of each major type of three-speed transmission case. The distinctive or incremental change from case-to-case is highlighted in bold.

| Part Number |

Type | Usage & Description | 1928 | 1929 | 1930 | 1931 |

|---|---|---|---|---|---|---|

| A-7006-A(R) | 1 |

|

1927 | n/a | n/a | n/a |

| A-7006-A | 2 |

|

July | n/a | n/a | n/a |

| A-7006-B | 3 |

|

Oct | ? | n/a | n/a |

| A-7006-B | 4 |

|

Dec | n/a | n/a | |

| A-7006-B | 5 |

|

n/a | March | ||

The Type 1 and Type 2 cases were used with the early multiple disc clutch and flywheel, and the Type 3, 4, and 5 styles were used with the single plate clutch and flywheel design.

Compared to the later single plate clutch design, the multiple disc clutch design also used different clutch housings (bell housings) and inspection covers, transmission main drive gears, and clutch actuation components including shafts and levers.

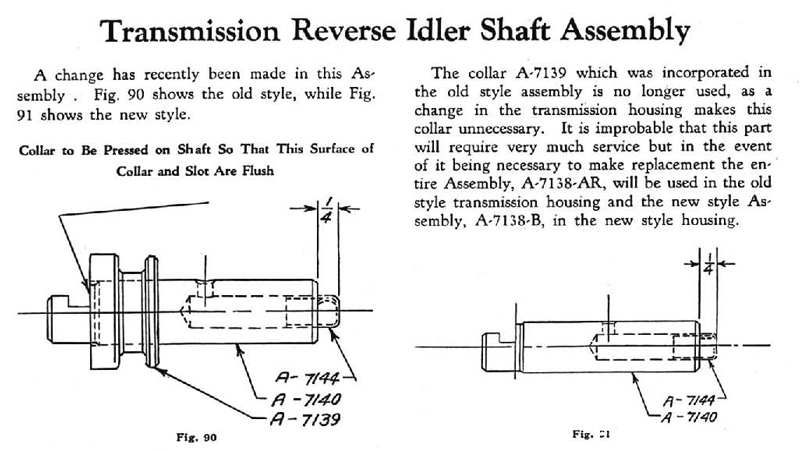

The illustration above shows the difference between the A-7138-AR reverse idler gear shaft used with the Type 1 case, and the and A-7138-B used with the Type 2 and Type 3 cases.

The Type 4 and early Type 5 cases used the same later idler shaft shown above, but without the oil scoop or cross drilling (under number A-7140), and in conjunction with a revised gear and bushing assembly providing for lubrication.

The later Type 5 cases used shafts with revised notches on the ends, and used a thinner shaft retainer and shorter bolt as shown in the illustration below.

Shown above are the notch and retainer designs of the Type 4 and subsequent early 1930 Type 5 reverse idler gear shaft A-7140, countershaft A-7111, and retainer A-7155 compared to the revised designs used with the later 1930 Type 5 transmission cases.

There are a variety of different three-speed gear shift housings (towers) as well, however all shift housings are functionally interchangeable with any three-speed transmission and case.

In addition to the Production type transmission cases shown above, there is also a very unusual style of Ford transmission case with a Service part number 46-7006. Please see the first link below for a web page showing and explaining the details of that case.

More related information on Ford Garage:

- For more Model A & B related information, use the Site Search box at the top or bottom of this page.

- Model A & Model 46 Service Transmission Case 46-7006

- Model B & Model 46 Transmission Case Variations

- 1928 to 1934 Double Sealed Transmission Ball Bearings

- 1928 Transmission Shift Tower & Lever

- Model B Transmission Shift Lever

- Model B & 46 Clutch & Transmission Housing Variations

- Model AA Four-Speed Transmission Clutch Housing

- Model AA Four Speed Transmission Case Cracks

- Model A Four Speed AA Transmission in a Model A Chassis

- Model A Ruckstell Dual High Transmission

- Model A Mitchell Synchronized Transmission

- Model A & B F-150 TOD Transmission Conversion ~ Tremec T170FT RTS

- Model A & B Rear Axle Gear Ratios

Vince Falter

April 2016