1931 Model A Slant Windshield Sedan

Ford Garage

Murray & Briggs Body Construction Differences

fordgarage.com

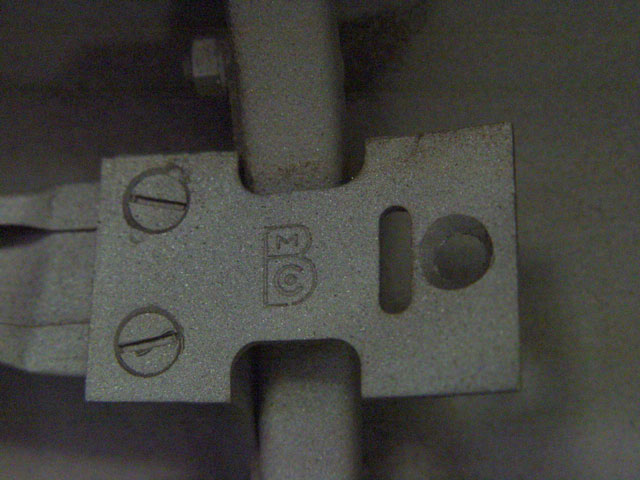

fordgarage.comThe great pic above shows the Briggs Manufacturing Company logo found on a small stamping in a 1931 slant windshield town sedan. Thanks to Scott Schmeiser for the use of his pic. This similar logo has been found on firewalls, brackets, and other body structural parts on other cars.

Unlike earlier Murray and Briggs sedans, the 160 Series slant window fordor bodies were produced by both suppliers and were virtually identical in construction and the parts interchangeable. The differences are in the subtle details, as illustrated in the example below.

There are two primary methods of distinguishing the between Murray and Briggs slant windshield fordor sedans. The first is the firewall body builder tag (which is often missing), and the second telltale difference is the use of machined D-nuts on the Briggs bodies versus the widespread use of sheet metal wrapped square cage D nuts on the Murray bodies.

The following pics show a side by side comparison of some of the detail differences between the same part made by two different Model A Ford body suppliers, Murray and Briggs.

The part shown for illustration is a LH front door window channel retainer, as used on the 1931 slant windshield Fordor Sedans 160A, B, & C, Victoria 190A, and Convertible Sedan 400A.

This retainer fits behind the trim garnish molding and attaches to the door. It keeps the felt glass run channel in position, and allows the glass to be loaded into the door through the window opening.

fordgarage.com

fordgarage.comShown above is a comparison of the same part, Murray on top, Briggs on bottom. Murray used sheet metal wrapped square cage nuts which were formed to fit and crimp into the D shaped holes in the part.

The Briggs bodies used the conventional one-piece machined D-nuts as used elsewhere on the Model A, and as also used in the bodies produced by Ford.

Both machined and cage style D-nuts were formed to fit and crimp into the same sized D-shaped holes in the part.

fordgarage.com

fordgarage.comAnother view. Murray on top, Briggs on bottom.

fordgarage.com

fordgarage.comThis view shows the differences in the style of D nut used, as well as differences in the way the section shape of the part was formed. Murray on top, Briggs on bottom. Note the extra fold and spot welds on the Briggs part.

fordgarage.com

fordgarage.comAbove is a close-up showing the raised reverse image Briggs Manufacturing Corporation logo stamped in the steel from the other side.

fordgarage.com

fordgarage.comClose-up of the Briggs Manufacturing Corporation logo stamped in the steel before it was formed into the part. Also shown is the form of the part section, and the lap where it is spot welded together.

fordgarage.com

fordgarage.comThe pic above shows the thread size 8-32 stamped on the outside of the square cage D-nuts as used by Murray Body Corp, as well as a close-up of the form of the Murray part section.

Please follow the link below for another page on Ford Garage noting additional differences between roof drip rail construction of 1931 Murray and Briggs bodied 160B Slant Windshield sedans.

More related information on Ford Garage:

- For more Model A & B related information, use the Site Search box at the top or bottom of this page.

- Model A & AA US Body Style Numbers & Body Builders Chart

- Model A Murray & Briggs S/W Sedan Roof Drip Rail Differences

Vince Falter

May 2003