Model A & B

Ford Garage

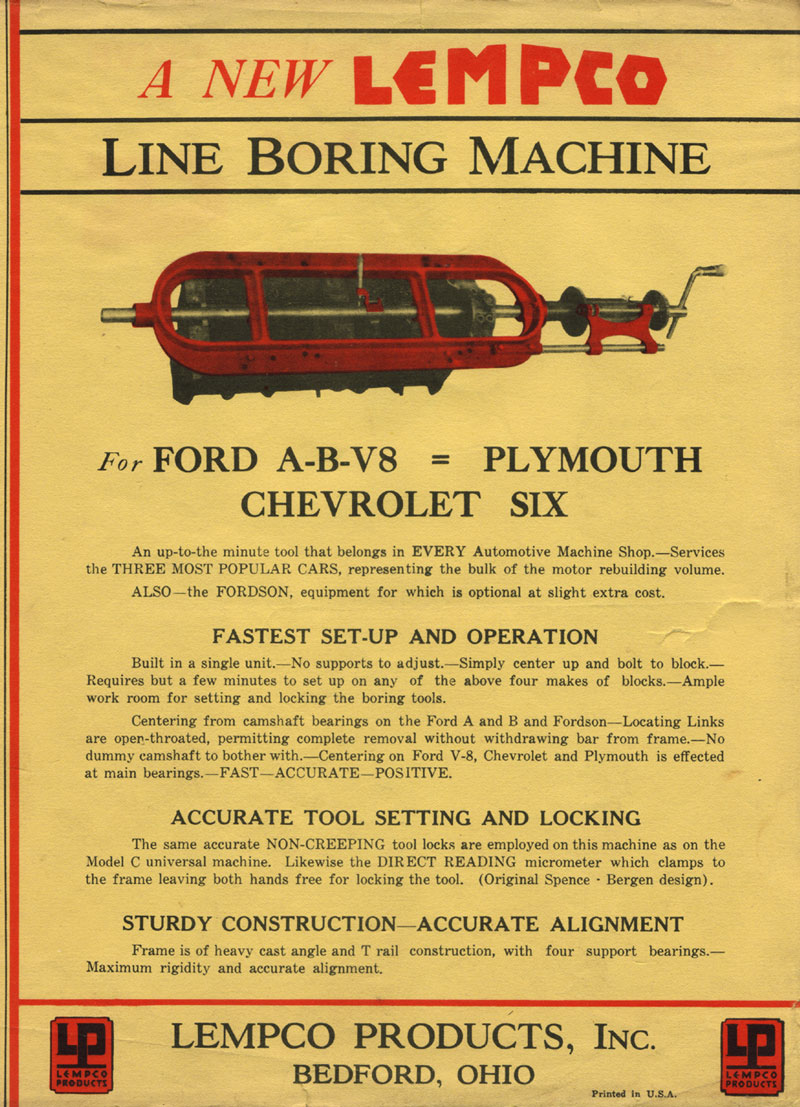

LEMPCO Align Boring Machine

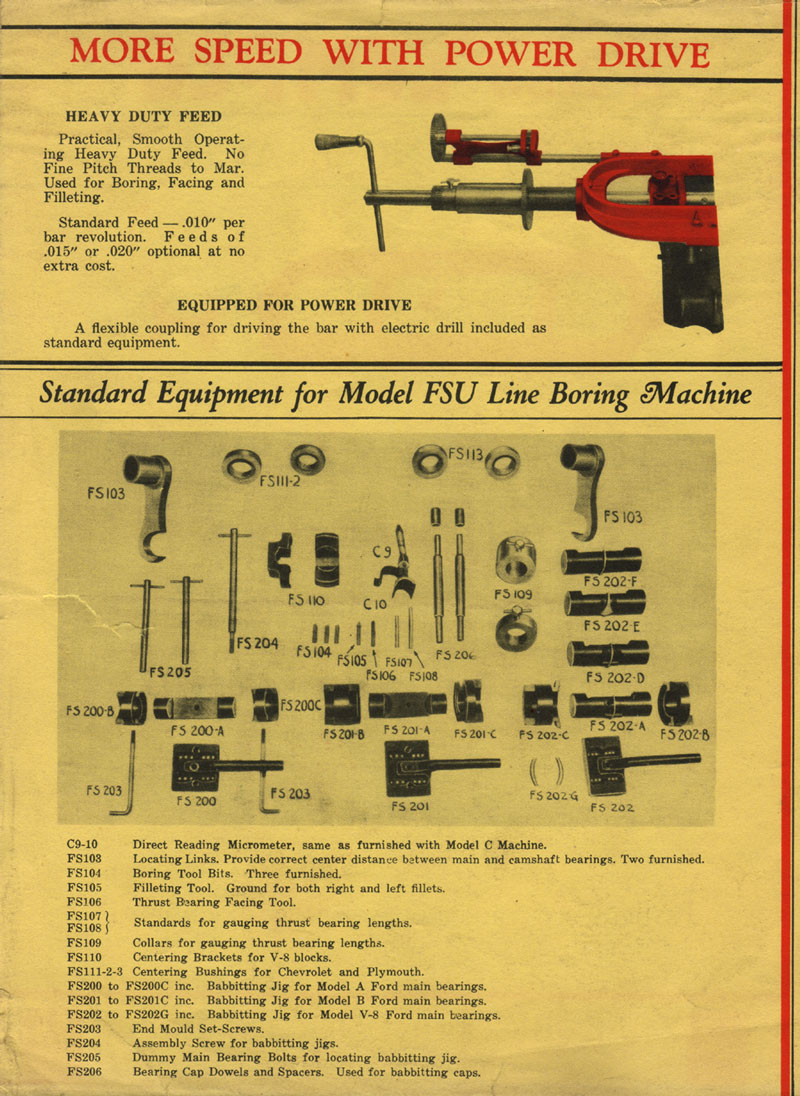

Model FSU (Fast Set Up)

For Babbitt Main Bearings

LEMPCO Align Boring Frame and Fixtures

Shown above is the brochure for the LEMPCO Line Boring Machine for machining the poured babbitt bearings on the Model A and B Ford engine block. The LEMPCO machine consisted of a portable purpose-built boring bar frame, bar, and fixtures for centering and location. In addition, it included tools and jigs for pouring the babbitted bearings prior to machining.

LEMPCO is the name of Lake Erie Metal Products Co. of Bedford, Ohio. LEMPCO was a producer of gears, worms, reamers, and other automotive and industrial parts, as well as automotive service equipment of the era.

When used on vintage Fords, the LEMPCO line boring bar and frame locating system relies on the location of the camshaft bores to directly space the boring bar centerline to the theoretical camshaft centerline.

The bar location fixtures insert into the cam bearing bores in the block (similar to Tobin-Arp bar locating fixtures) to center and support the boring bar centerline, according to the camshaft bore centerline location, and the pan rail datum surface.

In this way, the LEMPCO LBM fixtures directly locate and control the centerline dimension between the engine camshaft and crankshaft, which is important to maintain proper timing gear engagement and clearances.

In theory, this is a robust strategy for locating the main bearing boring bar (to the camshaft) in an engine design like a Model A Ford having a direct camshaft and crankshaft gear engagement, like a Model A Ford. However, the cam and crank alignment and engagement could be compromised when using this strategy to set up on a worn block.

If the block has excessive wear in either the front or rear camshaft bores, this method of locating off of the camshaft bores can introduce error in the proper placement of the boring bar in the block. This condition is often found on the front bore on Model A's and B's.

Measure cam bores for egg shape. Check your work carefully and confirm position before cutting.

Kwik-Way LBM Bar Locating Fixtures

fordgarage.com

fordgarage.comAlternatively, Kwik-Way LBM boring bar locating fixtures can be used with the LEMPCO boring frame to position the bar and frame according to the main bearing datum holes, instead of using the camshaft bores in the block.

fordgarage.com

fordgarage.comThe Kwik-Way LBM boring bar locating fixtures are shown mounted on a section of a Model A block in the pic above.

Both the LEMPCO FSU LBM and the Kwik-Way LBM main boring bars and frames use a 1-1/4" diameter boring bar.

Visit the links below on Ford Garage for more information about establishing and maintaining proper crankshaft and camshaft timing gear engagement and clearances.

More related information on Ford Garage:

- For more Model A & B related information, use the Site Search box at the top or bottom of this page.

- Model A & B Camshaft to Crankshaft Gear Alignment

- Model A & B Proper Crankshaft and Camshaft Positioning

- Model A & B Rear Main Bearing Caps

- Model A & B Kwik-Way LBM Main Bearing Boring Bar Fixtures

- Model A & B Tobin-Arp Main Bearing Boring Bar Fixtures

- Kwik-Way Line Boring Machine Operating Instructions

- Kwik-Way Line Boring Machine Parts List

- Model A & B AER Insert Main Bearing Data & Instructions

Vince Falter

August 2010