Model A, B & G28T

Ford Garage

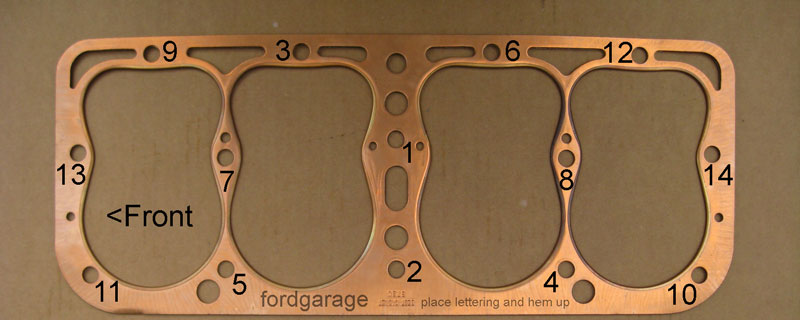

Cylinder Head Nut Tightening Sequence

fordgarage.com

fordgarage.comPictured above is the only 'officially' recommended engine cylinder head nut tightening sequence I have found published by the Ford Motor Company for Model A and B type engines. This image is from the 1948 Ford-Köln Lastwagen Ruhr Truck Instruction Book.

This engine is an improved G28T Model BB engine, first introduced in Germany during 1942. The G28T cylinder head is also interchangeable with that of US and British Model A & B engines, and Russian GAZ Model BB engines.

Ford did not publish actual torque values for the Model A cylinder head nuts, but the long accepted standard has been 55 lb-ft for a stock head, and as much as 65 lb-ft for a 6:1 high compression head.

It is recommended to initially torque the head in three passes following a sequence, going from 35 to 45 to 55 lb-ft. Then after some running and cool down cycles to re-torque to 55 lb-ft again because the gasket will take some compression and will lose some torque after initial use.

Pictured below is a somewhat different cylinder head nut tightening sequence which is commonly recommended by Larry Brumfield and by various modern Model A publications.

This sequence originated in the Model A era from Murray Fahnestock, who was the publisher and editor of the Ford Dealer and Service Field magazine in the 1920s-40s. FD&SF was a privately-published monthly Ford dealer service technical magazine, and was endorsed by the Ford Motor Company.

Also note that the combustion chamber hem of the gasket and any stamped lettering should always be placed 'up', in contact with the cylinder head, not the engine block.

⑬ .... ⑦ .... ① .... ⑧ .... ⑭

⑪ ... ⑤ .... ② .... ④ ... ⑩

More related information on Ford Garage:

- For more Model A & B related information, use the Site Search box at the top or bottom of this page.

- Model A & B Cylinder Head Gasket Guide comprehensive listing

- Model A & B Cylinder Head Compression Ratios

- Snap-on Cylinder Head Nut Wrench proper torque application tool

- Cylinder Head Flatness Requirements by Larry Brumfield

- Model A & B Cylinder Head Gasket Installation Instructions by Larry Brumfield

- Model A & B Cylinder Head and Distributor Pullers by Ron Cloat

- Model A & B Cylinder Head Stud Removal Tools

- Model A & B Broken Cylinder Head Stud and Bolt Removal

Vince Falter

August 2010