1930 Model A

Ford Garage

E.G.Budd Roadster 40-B Development

Shown here are a series of photos from the Budd Company archives showing the initial body panel development for Ford of the 1930 Model A Roadster, body style 40-B.

These photos were taken in late June, and early August 1929 in Budd's Philadelphia body plant.

Note the cowl with no stainless cowl band or provisions for one.

Deck lid open.

Note the windshield stanchions in the photo above.

Also note the center radiator support rod mounting provisions, the firewall stiffening rib design, the coil mounting provisions, and the 1929 style threaded gas tank filler.

Note the cowl side door hinges in the pic above. Reverse of the production design.

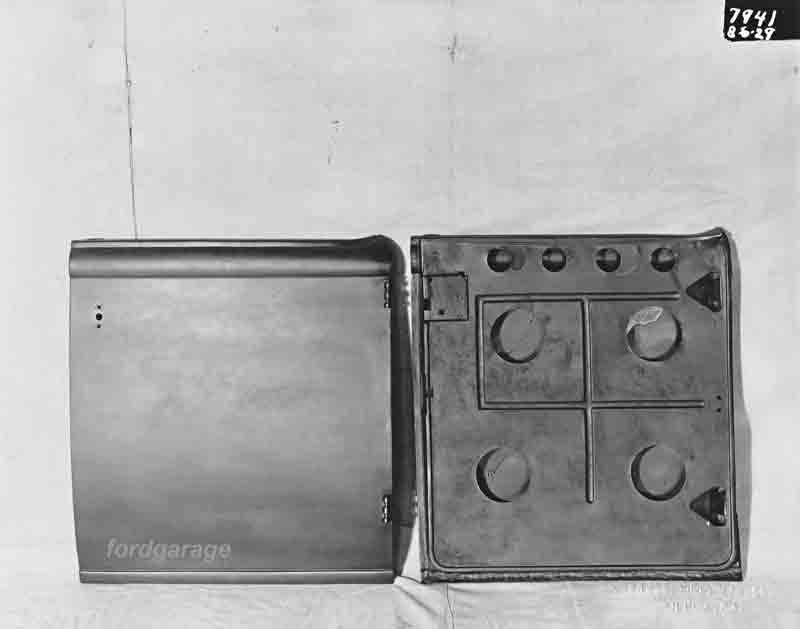

Door development in June 1929.

Quarter panels and the panels above and below the deck lid.

Budd was expert at developing all-metal bodies, sheet steel stampings, and panel subassemblies which did not rely on wood structure, and which could be shipped to assembly plants efficiently by rail.

Assorted floor pans and cross sill components shown above.

Cowl development in August 1929.

Note the cowl-side door hinges in the pics above. Production hinge design is shown; the reverse of the earlier June 1929 development design.

Door development in August 1929.

Refer to the links below for the development of the 1930 Phaeton body style 35-B, which also shared the roadster cowl and doors.

The Edward G. Budd company was based in Philadelphia, PA, and was an industry leader in the design and construction of all-steel auto bodies. Unlike Ford, GM, and others, Budd did not have access to vast reserves of timber for wood framed bodies, and so developed their expertise in sheet metal stamping and structural panel sub-assemblies capable of being efficiently nested and shipped by rail to Ford plants for final assembly. These modular panel constructed bodies used minimal wood content, primarily for top and trim.

In addition, Budd was a large supplier of completely assembled all-steel bodies to Chrysler Corporation in the 1920s and 1930s.

More related information on Ford Garage:

- For more Model A & B related information, use the Site Search box at the top or bottom of this page.

- Model A & AA US Body Style Numbers & Body Builders Chart

- Model A 1928 Budd Roadster 40-A Development

- Model A 1928-29 Budd Cab 82-A

- Model A 1929 Budd Deluxe Delivery 130-A

- Model A 1930 Budd Phaeton 35-B Development

- Model A 1930 Budd Prototype Slant Windshield Tudor Sedan 55-B

- Model A 1931 Budd Cab 82-B

Vince Falter

August 2015