Model A, B & V8

Ford Garage

Wheel Stud Installation Swaging and Removal Methods

The following pics show how the Model A Ford wheel studs are swaged or cold riveted into place on the brake drum and hub. This is done using a special swaging tool in a hydraulic press. Ford used this type of wheel lug stud attachment from 1928 to 1948.

I've used several presses, and am currently using a 50 ton KR Wilson Press which does the job at 20 -25 tons on the gage. I was previously using a 25 ton Dake Press which can do the job, though not as well as the KRW. A 20 ton import press will not be able to do a satisfactory job in my opinion.

The studs have a shoulder on them which is sheared and upset and tightens the stud in its hole, thus essentially riveting it in place. The studs are not serrated press fits like modern wheel studs. Modern serrated studs cannot be used in original Ford hubs and drums due to the fact that the flange thicknesses are very thin and also that the holes are significantly chamfered.

Additionally, there is virtually no clearance cross-car for the protruding head of a modern serrated stud. The head will hit, wear, rub, and interfere with the brake components mounted on the backing plate. This interference is often seen even on used original style hub and drum and stud assemblies which were designed with considerably more clearance.

fordgarage.com

fordgarage.comHere is the basic Model A rear drum stud, showing the shoulder and the anti-rotation key. The front studs are different, but are swaged the same.

fordgarage.com

fordgarage.comHub, drum, and studs.

fordgarage.com

fordgarage.comThanks to Don Turley for fabricating the terrific supporting and aligning fixture and the stud swage (or swedge) tools!

fordgarage.com

fordgarage.comPictured above is the support fixture in the press.

fordgarage.com

fordgarage.comThe pic above shows the un-swaged studs, hubs, and drum bolted together so that the hub and drum are properly positioned during swaging.

fordgarage.com

fordgarage.comClose-up of an un-swaged stud and the nose of the swaging tool shown in the pic above.

I originally bought the repro parts catalog swage tool, and found that it was not fit for use, typical of many repro type parts. It was case hardened mild steel, and not through-hardened. It had an excessively oversized ID to start with, and mushroomed open considerably more to over 0.540 inch, and it barely worked after that.

Max ID is 0.500 inch in my opinion, and the tool needs to be made of alloy steel and heat treated. The pic above is the tool Don made and heat treated for me 25 years ago. It was made at 0.500 inch ID, and I later wished I had it made yet a few more thousands smaller ID, but it works fine.

fordgarage.com

fordgarage.comHere is the stud shoulder after swaging. The stud on the left was defective and had insufficient rolled thread length at the bottom. It was removed and replaced in the following pics.

fordgarage.com

fordgarage.comNeed to remove a stud without warping a hub or drum? Do not use a big hammer to drive out studs! You will warp the hub flange.

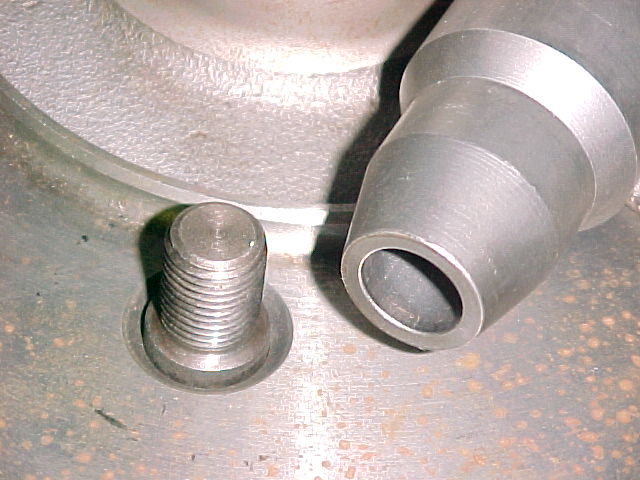

This is a carbide tip hollow end mill which will machine away the shoulder using a drill press or a hand drill. This was made from a swage cutter available from goodson.com. This prevents damage to valuable hubs.

fordgarage.com

fordgarage.comHere is the stud with the shoulder machined away so that it can be easily removed without distorting the hub or drum or affecting how true the braking surface runs.

fordgarage.com

fordgarage.comThis close-up shows the hollow end mill, a removed stud, and a new stud.

More related information on Ford Garage:

- For more Model A & B related information, use the Site Search box at the top or bottom of this page.

- Model A, B & V8 Wheel Stud Chart

- Model A, B & V8 Swage Cutting Tool on www.goodson.com

- Model A, B & V8 Dangerous Reproduction Lug Nut Characteristics

- Model A, B & V8 KR Wilson Rear Hub Puller

- Model A, B & V8 Truing Hubs on A Brake Drum Lathe

- Model A, B & V8 Brake Drum Lathe Rear Hub Mounting

- Model A & B Cast Iron Front Brake Drum Comparison

- Model A 1931 Cast Iron Rear Brake Drum Details

- Early V8 Hydraulic Brake Drums for 1932-1935 Wire Wheels

Vince Falter

April 2003